Hello,

Today I decided to keep busy on the 69 with the pressure hull. I have been patiently waiting for the Modelbrass upgrade....to my dismay, nothing! Not a shipping notice, not an e-mail confirmation, :'(not even a post card! Just the lonely Pay Pal statement mentioning "transaction complete".

Bill!!!!!!!!! You were spot on. Thank you.

Anyway, after Glenn had posted the bit about Archer, I was lurking around his 673 build site.

Modeling U-673 "Flak-trap" by Glenn Cauley

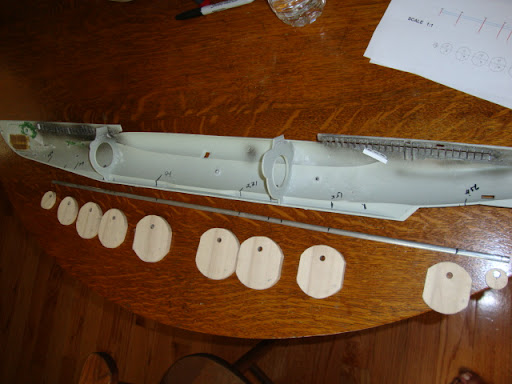

I found myself prior, attempting different methods of getting the non-hollow effect and was starting then scrapping, over and over again. The I saw Glenn's pressure hull layout. THANK YOU! After checking the supplies, I was only lacking the .080 sheet stock for the main ribs. Found some .25" Poplar instead. Off to work I went....

Scaled up the print, drilling, band saw and sanding

Carefull labeling as per Mr. Cauley's exquisite layout

Using a .25" Aluminum rod I had for the spine...

Dry-fitting....

Some fairing took place, and a bit more I presume. Not I need to remove the kit supplied ribs, so to make room for the continuous pressure hull skin. Now while I am WAITING FOR MY ORDER FROM MODELBRASS, for my BOTTOM VENTS, I will finish the skin and work on the saddle tanks and torpedo door framing.

Cheers!